Quality-driven endeavours lead to greater personal satisfaction and a sense of accomplishment. We at SPNG are committed to give the best in whatever we manufacture. A quality work lasts for years and continues to inspire many others.

In business and relationships, quality plays a crucial role in building trust and credibility. Our commitment towards quality products has built trust among our customers, they rely on us. Trust is the foundation of any successful relationship.

It means meeting customer needs and expectations consistently. It is the key for stability and leads to business growth. Instead of spreading ourselves thin by trying to do everything, we have concentrated to deliver the best in whatever we do.

Since inception, SPNG has focused in conserving natural resources by reforming standards to “Produce and Protect”. SPNG is in the field of manufacturing Steel products, Textiles, Solar Power and Horticulture products. To whatever we produce we recycle thereby preserving our natural resources and serving our mother land.

We manufacture green steel using ferrous scrap mix in the raw material chain conserving natural resources by reducing the need for mining and extracting new raw materials. Recycling helps to reduce greenhouse gas emissions associated with the production of new metals, as recycling requires less energy than the production of new metals from mining materials.

We produce 100% recycled polyester staple fibres consuming PET scrap. As part of our regenerative role of both producer and recycler, we are proud to recycle over 42 million PET bottles a year which are transformed into sustainable fibres.

Besides, every drop of water used in manufacture process is recycled through zero liquid discharge technology and used again in the process. Usage of solar power in its manufacturing process is another further honest step of SPNG towards its Produce and Protect standard.

SPNG is named after our inspirations Shri Pyare Lal and Shri Nand Kishore. They well said serving others helps those who give as well as those who receive. Service empowers people to put their talents into action for good purposes, bringing them fulfilment as they meet others’ needs. Their legacy was carried out by Lt. Shri Mithlesh Agarwal and is being followed by Shri Yogesh Kumaar Jindal. They all thought for the place where they live instead of moving to other States for business. Creating job opportunities through industries thereby serving their mother land. In words of Dieter F. Uchtdorf, “As we lose ourselves in the service of others, we discover our own lives and our own happiness.”

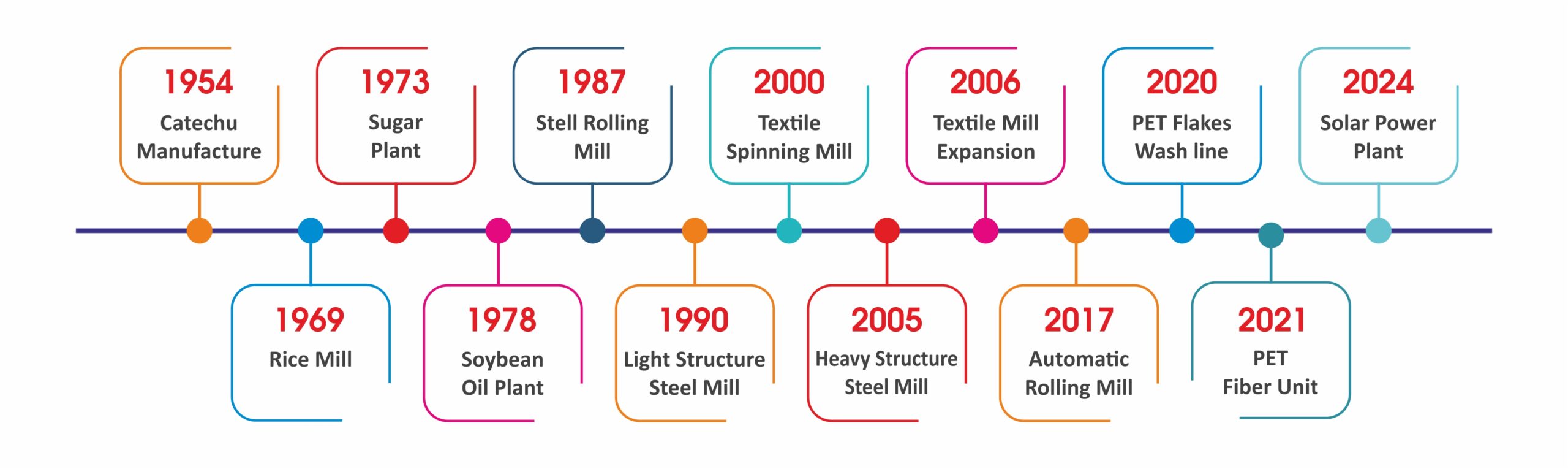

In 1954-1977, Shri Mithelesh Kumar Agarwal Ji, a young visionary from a prominent traditional business family, started giving new and advance shape to old traditional business by investing in manufacturing units of Catechu, Rice, Sugar, North India’s first soybean oil seed-based extraction plant in Uttarakhand (then Uttar Pradesh).

In 1978 first of its kind soybean oil seed-based extraction plant in Uttarakhand (then UP) was setup to manufacture edible vegetable oil.

In 1987, Regions first Steel Rolling Plant at Kashipur, Uttarakhand was set up to manufacture quality steel bars to meet the rising demand of steel in the region.

In 1990, light structure mill was setup to manufacture various steel products as angle, channel, square, round and square bar.

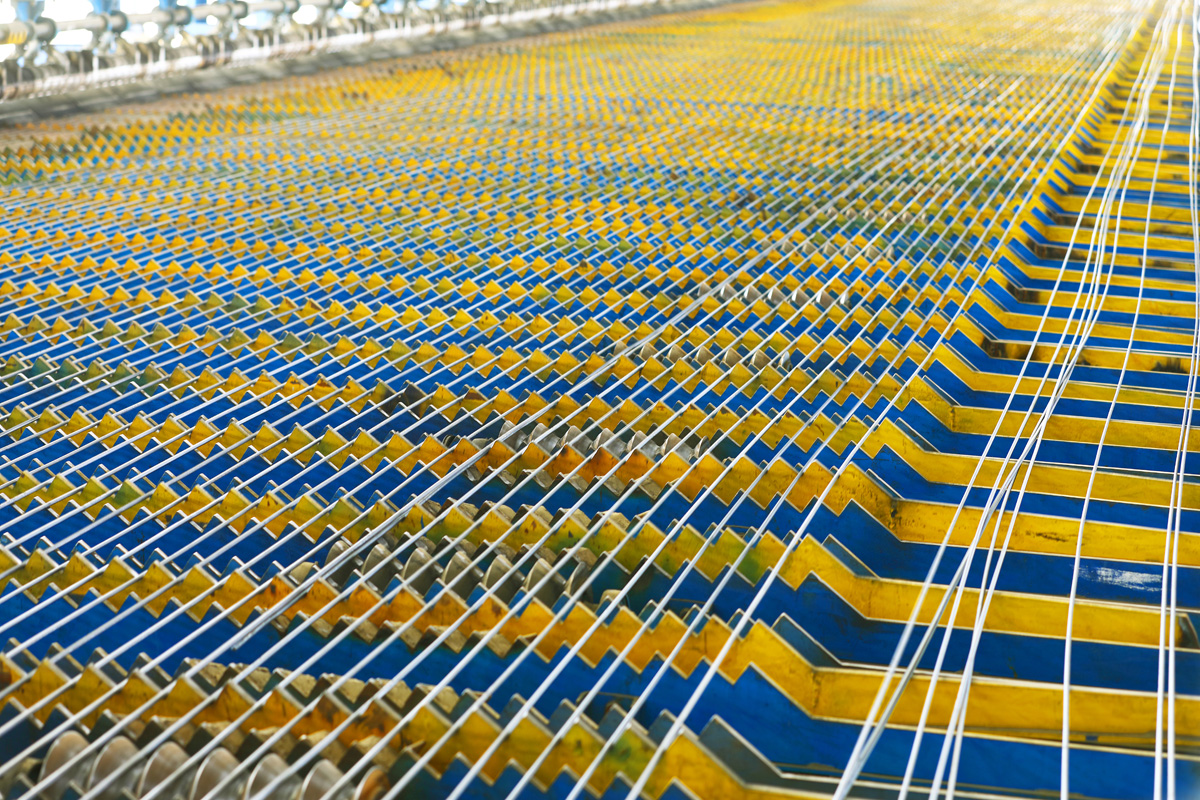

In 2000, with a vision of creating job opportunity for the locals though textile, spinning mill was set up producing polyester yarn.

In 2005, the steel product range was extended by setting up heavy structure steel plant manufacturing girders, channels, and casting of heavy equipment for sugar industries.

In 2006, the textile business was expanded with latest technology available, increasing the capacity and providing more job opportunities to the local population.

In 2017, automatic rolling mill was set up producing TMT bars using latest advanced technology with high precision.

In 2020, washing line was setup to recycle trash PET bottle converting them to pet flakes use to manufacture rPSF and other plastic products.

In 2021,the recycle pet fibre manufacturing unit started to produce wide rage of rPSF in multiple shade denier and cut length.

In 2024, the solar plant was installed to take care inhouse electricity requirement, thereby conserving the energy.